Polo Custom Products

Foam Materials

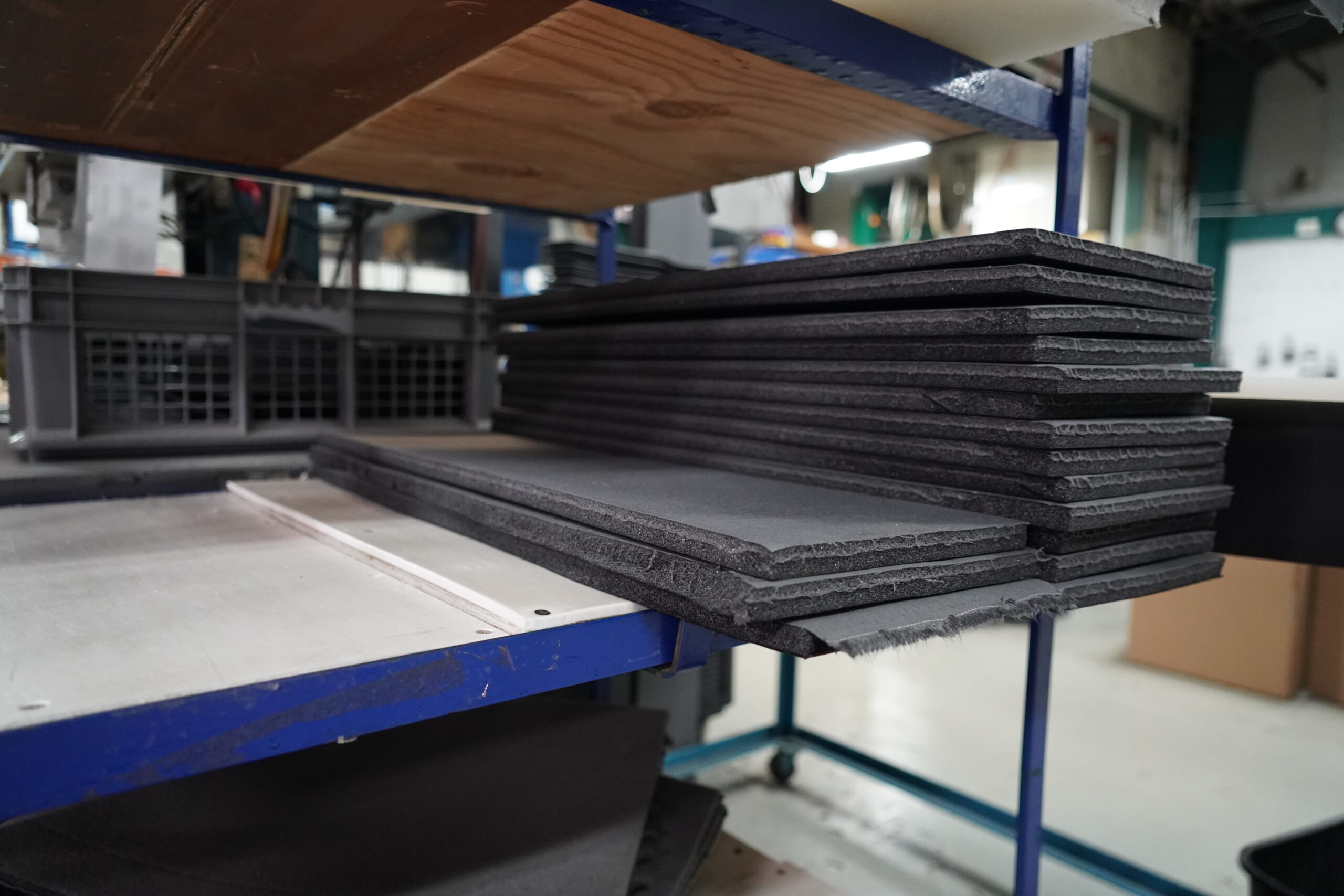

At Polo Custom Products, we collaborate closely with large OEM companies to custom manufacture products using the highest quality foam materials. Foam is essential for providing cushioning, structural support, and impact resistance across the various industries we work with. These include but not limited to, Medical, Government and Defense, Fire and Safety, Aviation, and Powersports. By selecting the ideal foam material for your project, we ensure

the final product meets the specifications, performance, durability, and comfort required by our partners.

We offer a large selection of foam materials, each suited for different applications. Open-Cell Foam, for instance, is flexible and breathable. It has tiny holes that let air flow through, making it comfortable and able to shape to your body. This foam is often used in our medical cushions, padding for protective gear, and soundproofing and much more. Its ability to mold to shapes makes it great for products that need to be comfortable and durable

In contrast, Closed-Cell Foam, such as EVA (Ethylene Vinyl Acetate), offers impressive shock absorption and water resistance. Its tightly sealed structure prevents water absorption and provides a more rigid, supportive cushioning solution. Our EVA foam is widely used in protective gear, thermoformed bag inserts, and high-performance products in powersports and military applications. Its durability and resistance to environmental factors like moisture and UV

exposure make it perfect for products that must endure tough conditions.

Another important material we offer is Crosslink Foam. This type of closed-cell foam undergoes a special chemical process that enhances its strength, resistance to heat, and long- term durability. Crosslink foam is used in industries like medical for instrument packaging, protective cases for our war fighters and even powersports seats and cases where high reliability and resistance to wear are required.

For more specific needs, Polyurethane (Urethane) Foam provides a wide range of densities and hardness options. Urethane foam is extremely versatile and can be tailored to provide either soft, flexible cushioning or firm structural support. It is often used in applications like seat padding in aviation, shock-absorbing components in power sports, and cushioning in medical devices.

Polyethylene Foam, a lightweight yet highly durable material, is frequently used in packaging, medical applications, and sporting goods. It is known for its impact resistance and resistance to moisture, making it a reliable option for protective cases and components that need to withstand environmental factors.

Lastly, EVA Foam stands out for its cushioning properties, flexibility, and UV resistance. This foam is commonly used in our Government and Defense and Fire and Safety industry because it offers comfort and long-lasting durability.

Keep in mind that Polo’s Product Development and Quality teams will sit down with you to discuss the correct material for your application. We are experts in our field and want to simplify the complex products that come through our doorway. We take pride in developing products that are built for manufacturability. We will assist you from a simple drawing or idea to full-scale production. We take pride in selecting the perfect foam material for every OEM project, ensuring product longevity, protection from environmental elements, and the ideal performance for each specific need. Once the optimal material is determined, our experienced team can craft a detailed manufacturing plan to bring your product to market quickly and efficiently. To explore our complete range of raw materials, click the Materials tab on our homepage.