Polo Custom Products

Heat Sealing Solutions

Choosing the Right Sealing Method

When it comes to sealing and bonding materials, there are several techniques to choose from. Each method has its own unique advantages and applications, making it essential to understand how they differ. Working with the Polo experts to choose the right method not only ensures the integrity and durability of the final product but also impacts production efficiency and cost-effectiveness.

Having a team like Polo on your side ensures you understand the unique characteristics and benefits of each sealing method. Our expertise is crucial for aligning your project’s specific needs with the most effective sealing solution, leading to a successful outcome.

Polo’s Sealing Capabilities

Polo provides a wide range of sealing techniques, expertly chosen to match the unique requirements of your project. Hot Air Welding, Impulse Sealing, Ultrasonic Sealing and RF welding are methods that Polo offers. Each method has its distinct advantages that can fast track the trajectory of your products manufacturability.

Reach out about our Sealing Capabilities!

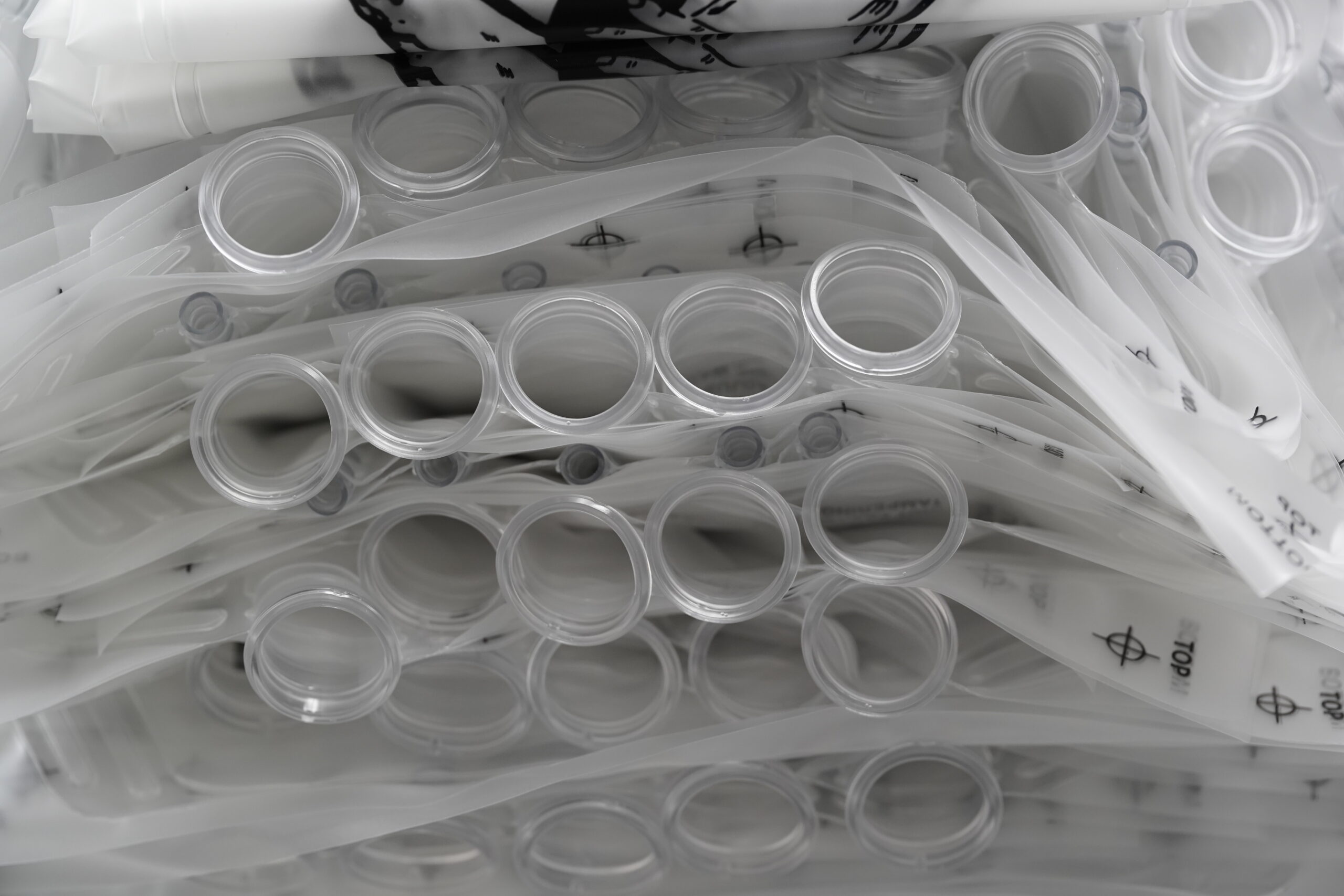

Heat Sealing Capabilities

Heat sealing involves applying heat and pressure to bond thermoplastic materials. Polo uses heat sealing to bond non-compatible materials by applying thermal adhesives which bonds the materials.

One of the primary advantages of Pols’s heat sealing method is its versatility. It is compatible with numerous thermoplastic materials, including but not limited to: Polypropylene, PVC, Polyethylene, PET and Polystyrene. Making it suitable for a broad range of packaging applications. Additionally, heat sealing provides excellent bond strength and can form durable seals that withstand environmental stressors such as moisture and temperature fluctuations or whatever strain could be present after production.

Heat sealing also offers a high degree of control over seal quality. Parameters such as temperature, pressure, and rest time can be precisely adjusted, ensuring consistent seals time and time again. Pair this with Polo’s quality and testing procedures, you have a product guarantee that is incomparable. This type of control is crucial in medical manufacturing, where the integrity of the seal can impact the product’s safety and effectiveness. In addition, heat sealing is relatively cost-effective and scalable, making it an attractive option for both small-scale and large-scale production.

Request a Quote today regarding your sealing needs!

The Polo Difference

What sets Polo apart is our ability to offer a wide range of sealing methods all under one roof. Whether it’s RF Welding, Ultrasonic Sealing, or any other sealing technique we offer, customers and prospects can witness firsthand our full spectrum of sealing technologies in action. This unique capability ensures we provide the best solution tailored to your production needs, regardless of volume.

How can Polo Help You?

Polo offers comprehensive, cutting-edge sealing opportunities. We are always working towards continuous improvement and adapting processes as needed when customers bring us new and exciting challenges. Our commitment to precision, innovation, and quality is evident in all our products. We’re fully compliant with ISO 9001:2015, ISO 13485:2016, and other quality standards and are dedicated to being your one stop shop for any innovative needs.

Please contact us with any questions or to request a quote!