Polo Latest

A Commitment to Quality and Testing

At Polo Custom Products, we are committed to offering exceptional quality to our customers. This commitment has led to long lasting partnerships with many industry leaders and government agencies seeking innovative high-quality custom manufacturing solutions.

Our Quality Management System

Polo Custom Products Quality Policy is: To safely build a quality product, on time, at a competitive cost. We believe that all employees play a vital role in the quality, service, delivery and performance of our products.

Polo Custom Products has developed and implemented a quality management system, which uses ISO 9001:2015, ISO 13485:2016 and FDA QSR 21 CFR Part 820 as the framework. These standards allow our organization to document and improve our processes to better satisfy the needs and expectations of our customers and stakeholders.

These standards ensure planning, operation and processes are controlled. Polo first received certification to ISO 9001 in 2002 and then in 2020, we added ISO 13485 certification, which is specific to medical devices.

ISO Standard Compliance and Our Business

ISO 9001:2015 specifies requirements for a quality management system where an organization:

- Demonstrates that it consistently provides products and services that meet customer and applicable statutory and regulatory requirements, and

- aims to enhance customer satisfaction through the effective application of the system, including processes for improvement of the system and the assurance of conformity to customer and applicable statutory and regulatory requirements.

ISO 13485:2016 specifies requirements for a quality management system where an organization:

- demonstrates its ability to provide medical devices and related services that consistently meet customer and applicable regulatory requirements, and

- is involved in one or more stages of the life-cycle, including design and development, production, storage and distribution, installation, or servicing of a medical device

Compliance with both standards is voluntary. Polo is compliant with the requirements of both standards and is registered as compliant to both standards. A third-party body, called a Registrar, audits each of our facilities once per year to verify conformity. And then we receive a certificate showing conformance to these standards.

The decision to become ISO registered is a business-driven decision. Quality and customer satisfaction are key priorities for today’s most successful organizations. In a competitive marketplace where efficiency pressures and consumer demands are increasing, quality can set us apart from the rest. Compliance to a globally recognized standard such as ISO 9001:2015 or ISO 13485:2016 is advantageous to our customers.

How Do We Measure Quality?

We monitor and measure Quality at two separate levels within our organization – the first is at the product level. Did we manufacture the product according to the customer requirements? We monitor this a few ways:

- Quality checks are performed on the production floor by production associates and operators on ½ hour or hourly rotation.

- Roving inspections are completed by Quality Technicians or Managers.

- Our Quality Control (QC) lab performs product testing on production lots.

- Dock audits are completed on inventory by quality to ensure all specifications are met, and incoming raw materials are inspected from a quality standpoint.

The second level of quality monitoring occurs at the Quality Management level – is the quality system meeting the defined objectives? Are we fulfilling our quality policy, which is to safely build a quality product, on time, at a competitive cost? At this level, we monitor things such as:

- Customer returns or complaints.

- The number of manufacturing defects and on time delivery to our customers.

- We perform internal audits of our processes against defined criteria to determine if we’re in compliance.

- We trend this data year over year to determine if we’re consistently improving or do we need to take specific actions to fix things.

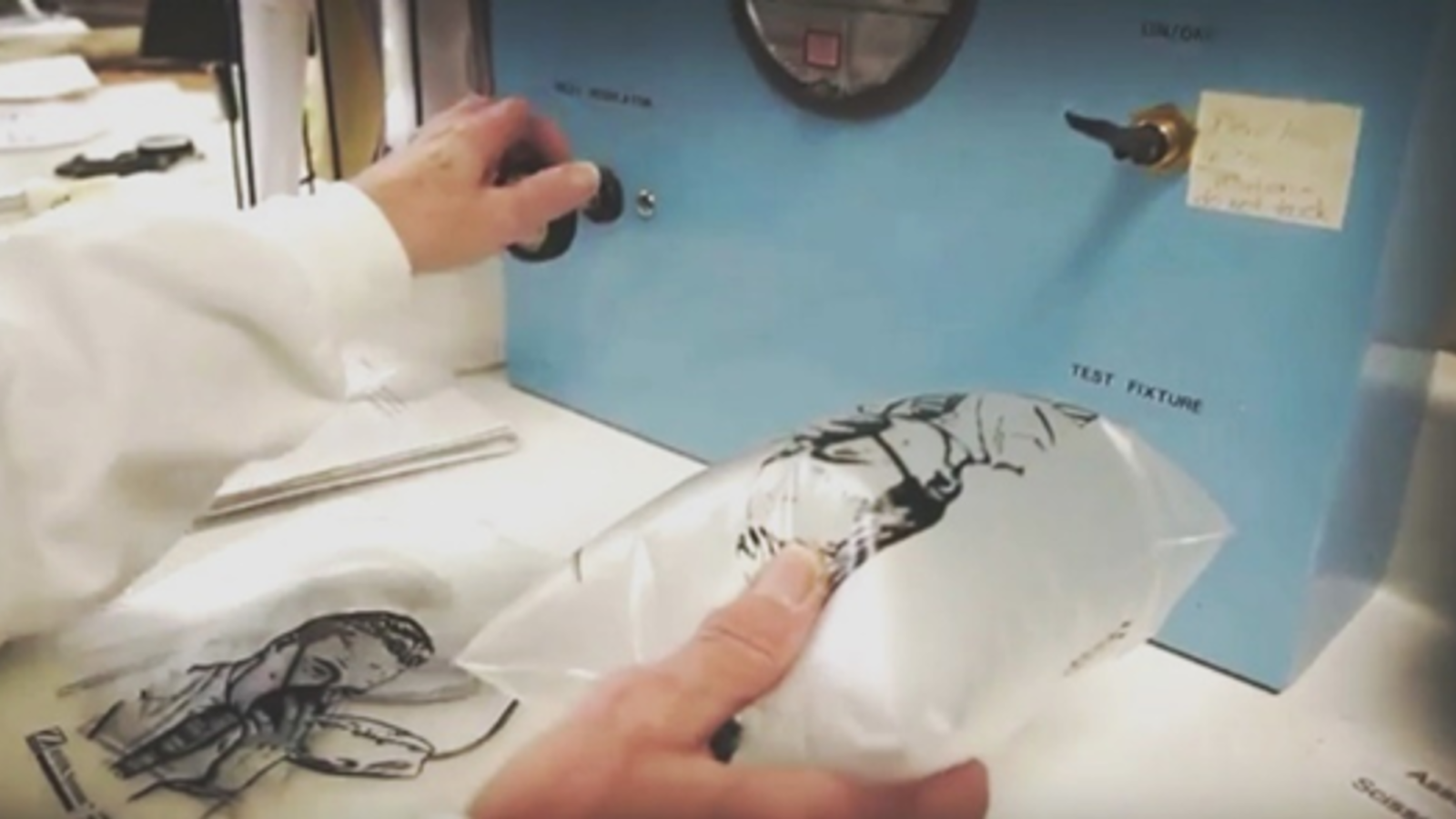

Product Testing and Methods

We utilize various test methods for testing product quality throughout product development and production. Our preference is to duplicate the test methods used by our customers. To this end, we like to know as much information as possible about our customers’ testing procedures, to ensure our testing is in alignment with theirs. If the product requires specialized test equipment, we like to use the same test equipment as our customers.

Pressure decay testing

- Two computerized machines with testing pressure capabilities up to 5.0 PSI. Most testing requirements are 1 PSI.

- Unit is placed between compression plates, air inflated to the established parameters, then machine calculates leak rate. Machine signals acceptance or rejection of unit by indicator lights.

- Testing parameters are established by customer requirement and engineering

Tensile Testing

- This type of testing is performed on all sealed products at the time of setup. Tensile testing is done to check seal integrity. Seal type, material properties, die shape, die condition, equipment condition and equipment setup all contribute to the quality of the seal.

- Measure material thickness and weld thickness. Specimens are cut at a 90-degree angle to the seal. The specimen is placed in the opening between the upper and lower jaw and pulled until the specimen fractures or material breakage occurs. The specimen is examined to determine if a peel occurred.

Air inflate/water dip

- The unit is inflated to established pressure then placed in water. Leak is determined by escaping air bubbles.

- Products which have concerns about pyrogens cannot be tested using water

Air inflate/manometer

- Unit is inflated and pressure is locked at the established parameter on the manometer (recorded by “inches of water”).

- The leak rate is determined by a drop in pressure during a timed test period.

Air inflate/burst test

- Unit is inflated, unrestricted, until material breaks next to the seal or the material ruptures

Weight application

- Unit is air or water filled, then flat surface placed on unit. Weight applied.

Visual and Dimensional Inspection

- The product is inspected against the customer’s drawings and Polo’s internal quality standards.

Quality is Our Commitment

At Polo, everyone belongs in the quality circle. Quality is involved very early on in the development process, to ensure that the manufacturing process and product design itself are compliant with the customer’s requirements, all regulatory requirements, as well as Polo’s own internal quality standards.

Once a product has rolled into production, Quality is responsible to ensure that the production process is followed and that a quality product with no defects is manufactured and shipped to the customer. We have a dedicated quality manager in each one of our manufacturing facilities, and then a team of Quality technicians and test lab technicians under the quality manager that support product inspection and testing.

If you are looking for a manufacturing partner as dedicated to quality as you are, please contact us today to learn more.