What We Do

Supply Chain Solutions for OEMs

In today’s fast-moving global market, OEMs face increasing pressure to reduce costs, improve efficiency, and bring products to market faster. Managing supply chain and logistics can become overwhelming and costly. Polo Custom Products offers a comprehensive supply chain solution for OEMs, providing everything needed to produce Custom Sewn, Sealed, and Thermoformed products. By partnering with Polo, OEMs can save valuable time, reduce costs, and improve product quality, allowing them to focus on the core of there business.

Contact us below to discuss how Polo can help streamline your supply chain and improve your manufacturing process!

Why Polo is Your Ideal Supply Chain Partner

At Polo Custom Products, we specialize in providing end-to-end supply chain management for custom manufacturing. Here’s how we help:

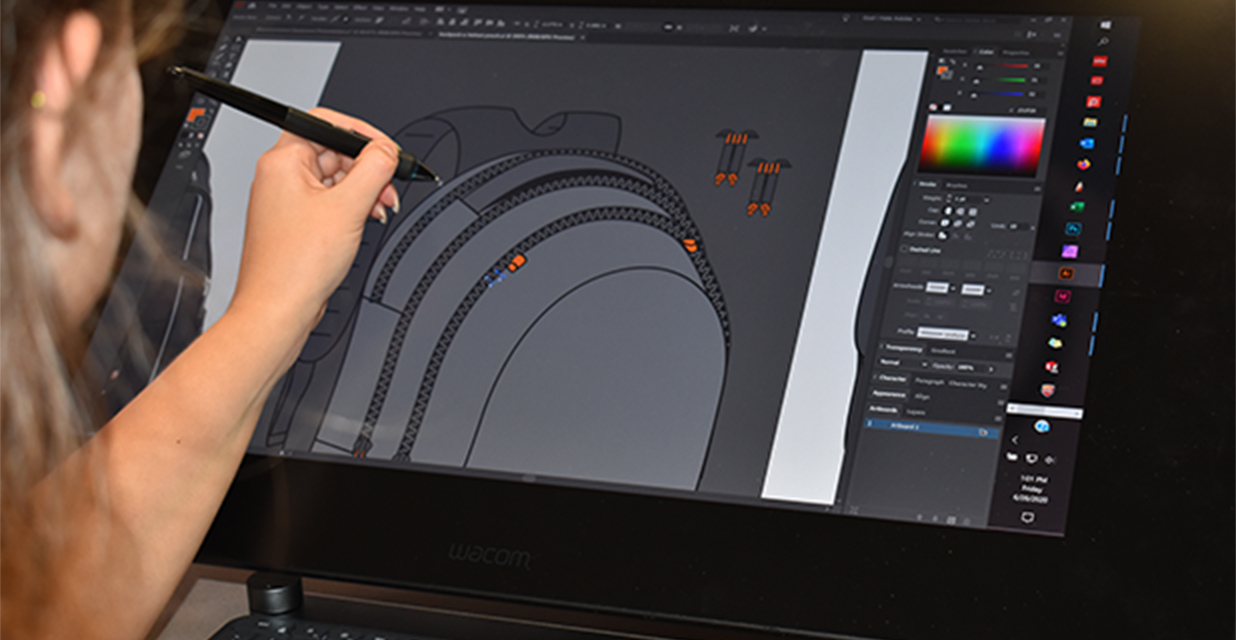

1. Full-Service Design and Product Development

We manage all aspects of Product design and Engineering for Sewn, Sealed, and Thermoformed products. Our team works closely with you to ensure that your product meets functional, aesthetic, and regulatory requirements, from concept to creations

2. Supplier Management and Sourcing

Polo Custom Products takes the complexity out of sourcing by managing your supply chain. Whether it’s Injection molding, CNC machining, Metal Stamping, or Vacuum Forming, we ensure that you work with reliable, high-quality suppliers. No more long travels, risking company time and money working with poor suppliers. We save you the time and effort of managing multiple suppliers.

3. Global Raw Materials Sourcing

With over 75 years of industry experience, Polo has built an extensive network of global suppliers for a wide range of raw materials. We offer everything from Standard Materials like nylon and polyester to Specialty Formulations such as Kevlar®, Medical-Grade Vinyl, and Sustainable Materials made from recycled products. Our sourcing includes Green Materials and Compliant Fabrics that meet industry standards like ISO, RoHS and REACH.

4. Logistics and Inventory Management

Managing logistics and warehouse space can be a major challenge. Polo offers both Domestic and International logistics management as well as warehouse space to ensure timely delivery of your products. Our efficient inventory systems reduce lead times and optimize storage, improving your production flow and lowering costs.

Click here today to discuss how our logistics solutions can streamline your supply chain!

The Polo Advantage: Time, Cost, and Risk Mitigation

By working with Polo, OEMs eliminate the need to manage multiple suppliers, helping you achieve significant cost savings and faster time to market. Here’s how:

- Reduced Complexity: Consolidating all manufacturing and sourcing operations with Polo minimizes the risk of miscommunication, delays, and errors. We simplify your operations, ensuring everything runs smoothly.

- Faster Time to Market: Our efficient supply chain management helps bring your products to market faster, allowing you to start generating sales earlier in the product lifecycle. With well over a 100 years’ experience within our Supply Chain team, your in the best possible hands.

- Cost Savings: While working with multiple suppliers might initially appear to save money, the hidden costs of managing each supplier—such as staff time and communication overhead—can quickly add up. Polo’s integrated supply chain reduces these hidden costs, providing a more cost-effective solution.

- Risk Mitigation: With global supply chains, risks such as material shortages, geopolitical disruptions, and logistical delays are inevitable. Polo’s dual-sourcing strategies, including partnerships in multiple regions, help mitigate these risks, ensuring your products are delivered on time, no matter the external challenges.

Polo believes in building strong partnerships with our suppliers. By maintaining clear expectations, encouraging open communication, and continuously improving our processes, we’ve established a supply chain that drives long-term success. Here are some key strategies we follow:

– Clear Expectations and Accountability

We work closely with our suppliers to ensure everyone is on the same page regarding delivery schedules, pricing, quality standards, and compliance. By setting clear expectations and holding all parties accountable, we avoid delays and misunderstandings.

– Regular and Transparent Communication

Open lines of communication are crucial for effective collaboration. We keep suppliers informed with regular updates, and we proactively address potential issues before they impact production. Our transparency builds trust and ensures smooth operations throughout the supply chain.

– Process Optimization

Our efficiency philosophy is simple: our ‘don’t do list’ is as crucial as our ‘to do list.’ This mindset helps us continually streamline operations and prioritize effectively. We evaluate our critical suppliers every six months. This ensures they meet our high standards and the expectations of our customers.

– Continuous Process Evaluation

We assess our processes regularly to ensure they are aligned with customer needs and industry best practices. This commitment to continuous improvement allows us to stay ahead of trends and challenges, making adjustments when necessary to maintain optimal performance.

Partnering with Polo Custom Products offers you an abundance of time and cost saving benefits. We manage it – so you don’t have to!

- Full service design, engineering and product development for sewn, sealed and formed products and non-core components

- Sourcing and supplier management of non-core manufacturing processes such as injection molding, blow molding, rotational molding, vacuum forming, metal stamping, CNC machining, extrusion, casting, welding and others

- Global raw materials sourcing and procurement from qualified suppliers

- Dedicated import business department and Asian Business Manager located in Shenzhen, China

- Multiple, complimentary manufacturing processes

- FAI, PPAP and APQP procedure coordination

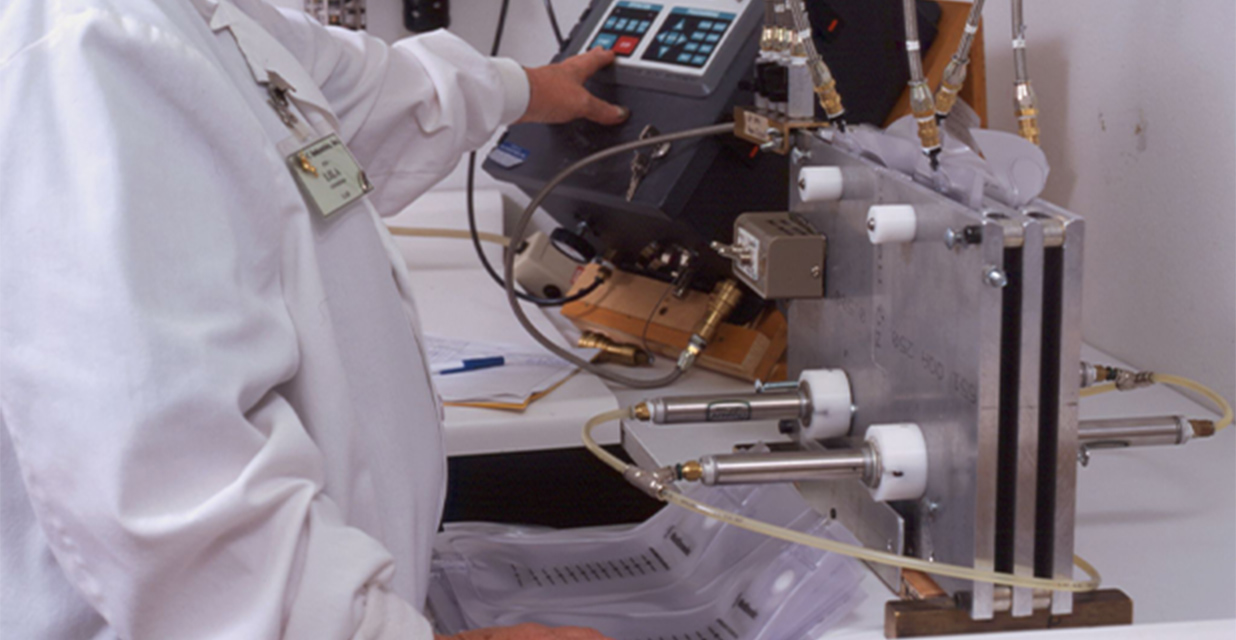

- In-house testing laboratory

- USA and international logistics management

- USA and international warehousing

- Tailored programs to meet your specific needs

Contact Us Today

Contact Polo Custom Products or Request a Quote Today to learn about our manufacturing capabilities, how we can accelerate your time to market, and drive long-term success for your business. Let us handle the logistics, so you can focus on what you do best—innovating and growing your brand.

Get started right here!

What We Do

Custom Since 1947

In addition to our sewing capabilities, Polo Custom Products has the ability to design and procure non-core components that work in conjunction with a sewn component. Examples include injection molded or blow molded trays and tubs, metal stamped brackets, CNC machined parts, specialty packaging and others.

We're all you need.

Turn to us, we specialize in custom product manufacturing and can help you source materials as well.